Yinber 8500B on line used ctp machine+bridge+processor+stacker,price of kodak ctp machine

Item No.: Yinber 8500B

Max./Min. Format: 1160x 940m (46”x 37inch/ mini. 350x 400mm (14inchx 16”)

No.of Lasers: 48

Productivity: size 1130x 800mm plates/ hour 24 Pieces

Laser Source: 830nm

Resolution: 2400 dpi (Resolution can be customized)

Loading System: Semi-Auto

Plate Requirement: 0.15-0.4mm(UV plates, no brand requirement)

Interface: 1-bit Tiff interface and direct workflow driver, support CIPC/CIP4

Power: AC220-230V,50-60hz, 5.5KVA

Environment: Temperature: 20-25 C degree, Humidity: 40%-80%

Size: 2020mmx 1000mmx 930mm

Net Weight: 1500kg

ctp plate making machine advantage:

3. Unlike traditional single-row optical fiber we arranged our optical fibers in a double-row position which brings us more saturated dot.

4. The same with Kodak we adopted real-time auto-focus technology.

Auto-focus brings us not only wider adaptability on plates but also more saturated dot.

If the drum happens to deform or plates not flat auto-focus can make up these flaws.

6. To ensure a high registration accuracy we adopted non linear correction technology and we also delayed our light-spot to make it come true.

7. High-power diodes.

Unlike most manufacturers used 1w diodes for CTP machines and 70mj (200mW) diodes for CTCP machines we use 2W diodes for CTP machines and 120mj (300mW) for CTCP machines.

Based on usual use higher power diodes can expect a longer life and not so easy to get aged.

8. Intelligent operation becomes reality. ( Remote diagnose)

Through “ Teamviewer” our technicians can real timely share data with customers computer thus to diagnose their CTP equipment.

9. We used built-in bearing to support our drum which brings us higher stability and accuracy when the drum rotates in a high spped without a big deviation.

10. We used top-class accessories of the world in all our equipment which brings our products stable performance and long life.

-Fuji motor from Japan;

-Lasermech thermal diodes from USA;

-Nichia UV diodes from Japan;

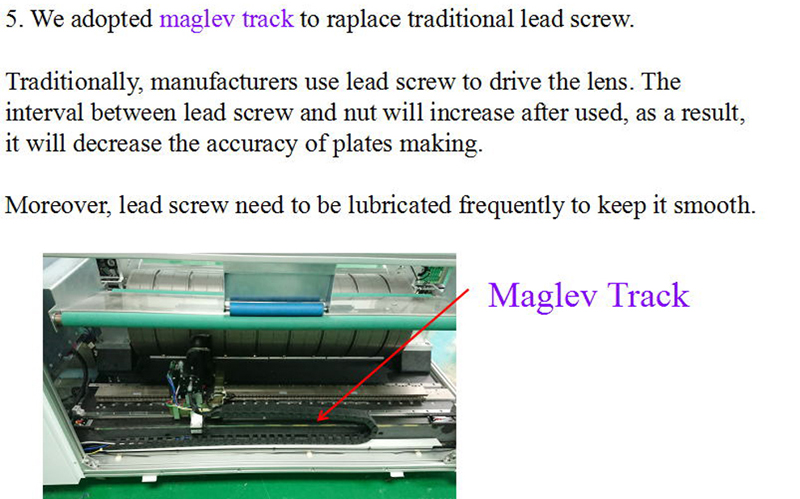

-Maglev system and bearings from Germany;

-Sensors from Spain.

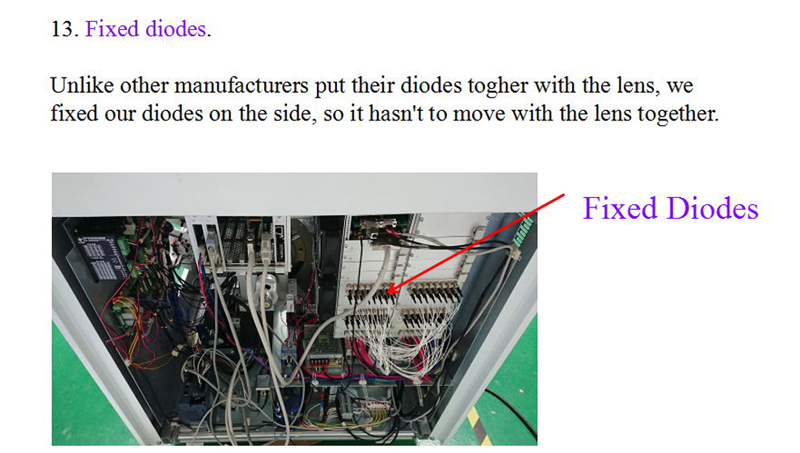

Unlike Kodak making their diodes as a whole if any one separate single diode got a problem we just need to replace the broken one that can save a lot cost.